2-3 WORKING DAY DELIVERY

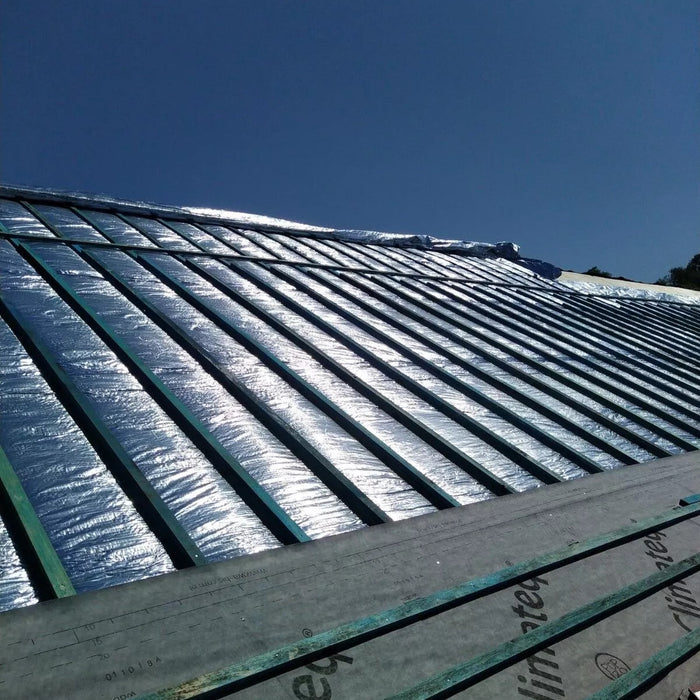

In the world of construction and architecture, every component plays a vital role in ensuring the longevity and durability of a structure. Among these crucial elements, roofing breather membranes stand out as unsung heroes, silently safeguarding buildings against the elements....

As we better understand the impact of changes to the design of the building envelope as a whole, some experts are predicting a return to traditional 1F felt.

When breather membranes replaced 1F as the top-selling roof felt, they were considered the wonder product. The fact is that today, most roofers would not consider anything else. As we begin to understand some of the limitations of breather membranes, many roofers and architects are predicting that roofers will return to traditional under-tile felt.

What is a Breather Membrane?

In the same way that a gore-tex jacket protects a walker or a cyclist, a breathable membrane protects your building from wind, rain and condensation.

With the improvement of quality and the tightening of building regulations, modern properties are becoming ever more airtight. This is great for reducing cold drafts and your heating bills. However, a negative impact is that the steam created by cooking, showers and the very air you breathe, has no-where to escape but upwards into your roof.

Address

Harrison Way, Matlock, Derbyshire, DE4 2LF

Email

sales@ashbrookroofing.co.uk

Phone

01629 732988

Order Online

24/7 hours a day